고정 헤더 영역

상세 컨텐츠

본문

One example of the use of activity costs is in manufacturing. A manager may be asked to evaluate of each product produced by a factory.

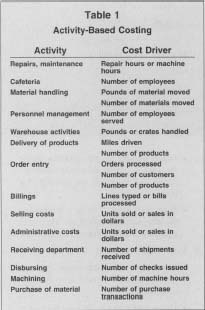

(ABC) is a common method for determining those production costs. ABC defines production as consisting of a variety of activities, and it assigns costs to those activities. For example, machine set-up might be one activity associated with the production of a particular product. The cost of set-up would be one cost included in an activity cost pool. Purchasing materials might be another cost assigned to the pool.

Assigning costs accurately is important to determine the profitability of products and subsequently to make rational production decisions. ABC differs from traditional costing methods.

Traditional costing is product-based and period-based. Product-based costs include materials, labor, and overhead while period-based costs include. These are charged against revenue for each accounting period. Allocating these costs to the production of products can produce distorted estimates, according to some managers, especially if a factory produces many different products. For a company with a single product, however, traditional costing and ABC would produce similar product cost estimates. The advantage of ABC is that it ties activity costs more directly to production.

It achieves this by removing the distinction between product and period-based costs. In addition, under ABC, products are not allocated costs of unused capacity. Under traditional costing methods, some portion of purchasing costs might be assigned to a product regardless of how much actual purchasing activity was required. ABC would seek to assess actual purchasing activity associated with a particular product. In addition, unused capacity might also be assigned to a product, potentially distorting its cost.

What Is A Cost Pool

Cost Driver.1.COST DRIVERSCOST DRIVERS&&COST BEHAVIOURCOST BEHAVIOURDr. Rana SinghDr.